Introduction to Milspec Wire M22759/16 and M22759/32

When it comes to high-performance electrical applications that demand reliability and durability, Milspec wires are the go-to solution. Among the various types available, M22759/16 and M22759/32 stand out for their exceptional quality and unique characteristics.

Understanding Milspec Wire M22759/16

Milspec wire M22759/16 is a high-temperature wire that features a tin-coated copper conductor. This wire is known for its excellent resistance to extreme temperatures, chemicals, and abrasion. It is commonly used in aerospace, military, and other demanding applications where reliability is critical.

Exploring Milspec Wire M22759/32

Milspec wire M22759/32 is a versatile wire known for its exceptional flexibility and resistance to environmental factors. It features silver-plated copper conductors and is suitable for a wide range of applications, including aerospace, defense, and industrial settings.

Unique Aspects of Milspec Wires M22759/16 and M22759/32

Both M22759/16 and M22759/32 wires conform to stringent military specifications, ensuring consistent quality and performance. These wires are designed to withstand harsh conditions, making them ideal for mission-critical applications where failure is not an option.

Automotive Applications of Milspec Wires M22759/16 and M22759/32

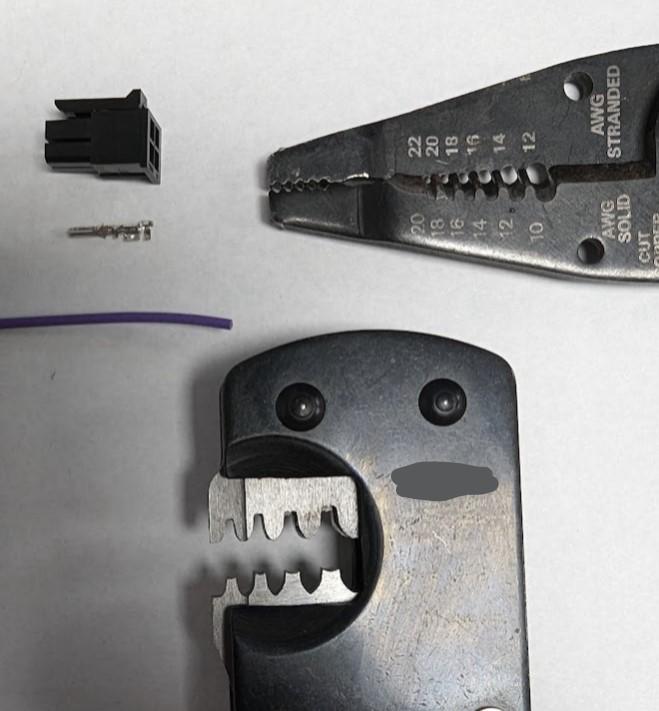

In the automotive industry, where reliable electrical connections are crucial for vehicle performance and safety, Milspec wires M22759/16 and M22759/32 find important applications. These wires are designed to withstand the challenging conditions of automotive environments, making them an excellent choice for various automotive wiring needs.

Engine Compartment Wiring

Milspec wires M22759/16 and M22759/32 are commonly used in the engine compartment of vehicles due to their high-temperature resistance and durability. They can withstand the heat generated by the engine and other components, ensuring reliable electrical connections for critical systems like fuel injection, ignition, and sensors.

Chassis Wiring

For wiring applications in the chassis and undercarriage of vehicles, Milspec wires M22759/16 and M22759/32 are preferred for their resistance to abrasion, chemicals, and environmental factors. These wires provide stable electrical connections for systems such as lighting, ABS brakes, and electronic stability control.

Interior Wiring

Inside the vehicle, Milspec wires M22759/16 and M22759/32 are used for various interior wiring needs, including power distribution, entertainment systems, and communication modules. Their reliability and durability ensure consistent performance in the diverse conditions found within a vehicle’s cabin.

Benefits of Using Milspec Wires in Automotive Applications

1. **Reliability:** Milspec wires M22759/16 and M22759/32 are designed to meet strict quality standards, ensuring reliable electrical connections in automotive systems.

2. **Durability:** These wires can withstand vibrations, temperature fluctuations, and exposure to oils and chemicals commonly found in automotive environments.

3. **Safety:** By using Milspec wires in automotive wiring, manufacturers can enhance the safety and performance of vehicles, reducing the risk of electrical failures and malfunctions.

In the automotive industry, the use of Milspec wires M22759/16 and M22759/32 offers numerous benefits, from enhanced reliability and durability to improved safety and performance. By incorporating these high-quality wires into automotive wiring systems, manufacturers can ensure that vehicles operate smoothly and safely in various conditions, making them a trusted choice for automotive applications.

Potential Uses of Milspec Wires M22759/16 and M22759/32

1. Aerospace Applications: Due to their high-temperature resistance and durability, Milspec wires M22759/16 and M22759/32 are commonly used in aircraft wiring systems, avionics, and other aerospace applications.

2. Military Equipment: These wires are well-suited for military equipment that operates in rugged environments. Their ability to withstand extreme conditions makes them a reliable choice for military communications, radar systems, and more.

3. Industrial Equipment: Milspec wires M22759/16 and M22759/32 are also used in various industrial settings where reliability and performance are essential. They are suitable for use in control systems, robotics, and other critical industrial applications.

Milspec wires M22759/16 and M22759/32 are top-quality wires that offer exceptional performance and durability. Their unique characteristics make them ideal for a wide range of applications in aerospace, military, and industrial sectors. By choosing these wires, you can ensure reliable and long-lasting electrical connections in even the most demanding environments.