When it comes to electrical systems, vehicles like cars and boats have distinct requirements and considerations due to their different environments and functions. Wiring these systems involves unique challenges and considerations to ensure safety, reliability, and optimal performance. Let’s delve into the key differences between wiring a car’s electrical system and a boat’s electrical system.

Wiring a Car’s Electrical System

Cars are designed for use on land and operate in a relatively sheltered environment compared to boats. Here are some key points to consider when wiring a car’s electrical system:

1. Voltage System

Cars typically operate on a 12-volt electrical system, with some modern vehicles incorporating 48-volt systems for specific components like mild hybrid systems. The wiring and components in a car are tailored to this voltage range, ensuring compatibility and safety.

2. Vibration and Temperature

Cars experience vibrations and temperature variations during operation, which can impact the reliability of electrical connections. Wiring harnesses in cars are designed to withstand these conditions and are often secured and insulated to prevent damage or shorts.

3. Electrical Loads

Cars have a variety of electrical loads, including lights, sensors, entertainment systems, and power accessories. Proper wiring design is crucial to ensure that each component receives adequate power without overloading the system.

4. EMI/RFI Protection

Electromagnetic interference (EMI) and radiofrequency interference (RFI) from various sources can affect a car’s electrical systems. To mitigate these issues, cars may incorporate shielding and filtering in the wiring to maintain signal integrity and prevent disruptions.

Wiring a Boat’s Electrical System

Boats operate in a harsher environment compared to cars, with exposure to water, salt, and constant motion. Here are some key considerations for wiring a boat’s electrical system:

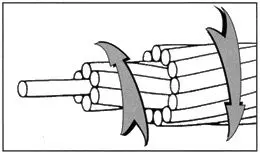

1. Marine-Grade Components

Due to exposure to water and corrosion, boats require marine-grade electrical components and wiring that can resist moisture and saltwater damage. Corrosion-resistant materials like tinned copper are often used to ensure longevity.

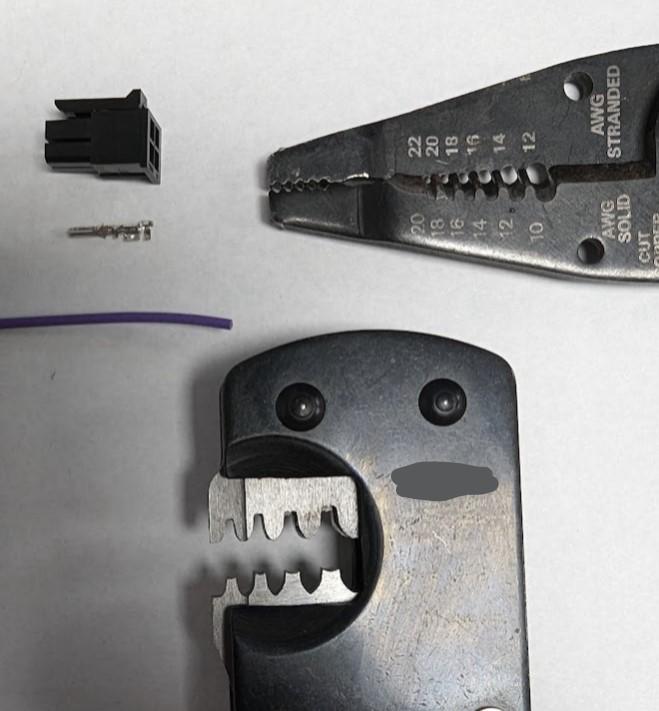

2. Water Resistance

Waterproof and water-resistant connectors, junction boxes, and wiring are essential for boat electrical systems to prevent short circuits and electrical failures. Proper sealing and insulation are critical to protect the system from water ingress.

3. Grounding

Boats require specific grounding techniques to prevent electrolysis and corrosion caused by electrical currents in the water. Isolating critical electrical components and using corrosion-resistant grounding points are common practices in boat wiring.

4. Compliance with Regulations

Boat electrical systems must comply with marine safety standards and regulations to ensure the safety of passengers and the vessel. Proper wiring practices, circuit protection, and installation techniques are essential to meet these requirements.

In conclusion, while both cars and boats have electrical systems that serve similar functions, the unique operating environments and conditions of each vehicle type necessitate specific considerations in wiring design and implementation. Whether on land or water, ensuring a well-planned and properly executed electrical system is crucial for the safety, performance, and longevity of both cars and boats.