The Importance of Wiring Gauges in Electrical Systems

When it comes to electrical wiring, the gauge of the wire plays a critical role in determining its suitability for specific applications. The gauge of a wire refers to its diameter or thickness, and it is an essential factor to consider when designing and installing electrical systems. In this blog post, we will delve into the significance of wiring gauges and explore their impact on electrical performance and safety.

What is Wire Gauge?

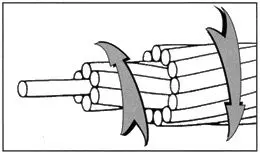

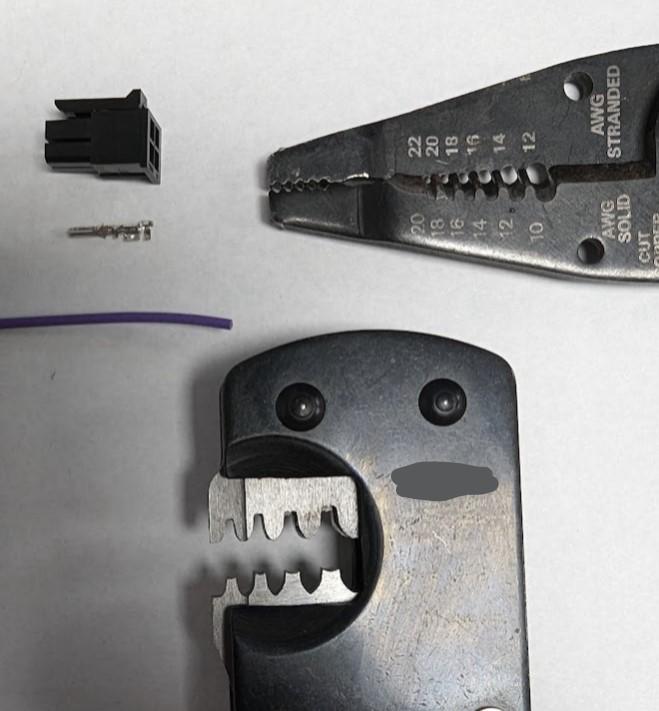

Wire gauge is a measurement of the diameter of a wire. It is typically denoted by a numerical value, with lower numbers representing thicker wires and higher numbers representing thinner wires. The gauge of a wire influences its electrical resistance, current-carrying capacity, and voltage rating. In the United States, wire gauges are standardized according to the American Wire Gauge (AWG) system, while other regions may use different standards such as the British Standard Wire Gauge (SWG).

Current-Carrying Capacity

One of the primary considerations when selecting a wire gauge for a specific electrical application is its current-carrying capacity. Thicker wires have lower electrical resistance, allowing them to carry higher currents without overheating. Conversely, thinner wires with higher resistance are suitable for lower current applications. Choosing the appropriate wire gauge ensures that the wire can safely carry the expected load without the risk of overheating or damage.

Voltage Rating

In addition to current-carrying capacity, the gauge of a wire also affects its voltage rating. Thicker wires with lower resistance can withstand higher voltages, making them suitable for applications that require power transmission over long distances or at elevated voltages. Understanding the voltage rating of different wire gauges is essential for ensuring the safety and reliability of electrical systems.

Practical Considerations

When working with electrical wiring, it is crucial to select the right wire gauge based on the specific requirements of the application. Factors such as the length of the wire run, the magnitude of the current, and the environmental conditions must be taken into account when determining the appropriate gauge. Using a wire that is too thin for the intended purpose can lead to excessive voltage drop, overheating, and potential fire hazards, while using a wire that is overly thick can lead to unnecessary costs and installation challenges.

Conclusion

In conclusion, the gauge of electrical wiring is a fundamental aspect of electrical system design and installation. By understanding the implications of wire gauge on current-carrying capacity, voltage rating, and practical considerations, electrical engineers, electricians, and DIY enthusiasts can make informed decisions when selecting and installing wires for various applications. Proper attention to wire gauge ensures the safety, efficiency, and reliability of electrical systems, making it an indispensable consideration in the field of electrical engineering and construction.