Introduction

Circuit boards are the backbone of electronic devices, serving as a platform for connecting components and enabling the flow of electricity. The design of a circuit board plays a crucial role in the functionality, reliability, and performance of the electronic device it powers. A well-designed circuit board can ensure optimal performance, longevity, and ease of troubleshooting, while a poorly designed one can lead to malfunctions, failures, and costly redesigns. In this article, we will explore the key factors that differentiate a good circuit board from a bad one, focusing on variables such as poor tracing, poorly placed components, poor use of grounding or power, and overly complicated tracing.

Poor Tracing

Tracing refers to the paths or routes on a circuit board that connect the various components together. Good tracing is essential for the efficient flow of electricity and signals, while poor tracing can lead to issues such as signal interference, voltage drops, and signal delays. In a bad circuit board design, poorly laid out traces may be too close together, causing crosstalk or interference between signals. Additionally, traces that are too long or have sharp angles can introduce impedance mismatches and signal degradation. To ensure good tracing, designers must pay attention to trace width, spacing, and length, following best practices to minimize signal integrity issues.

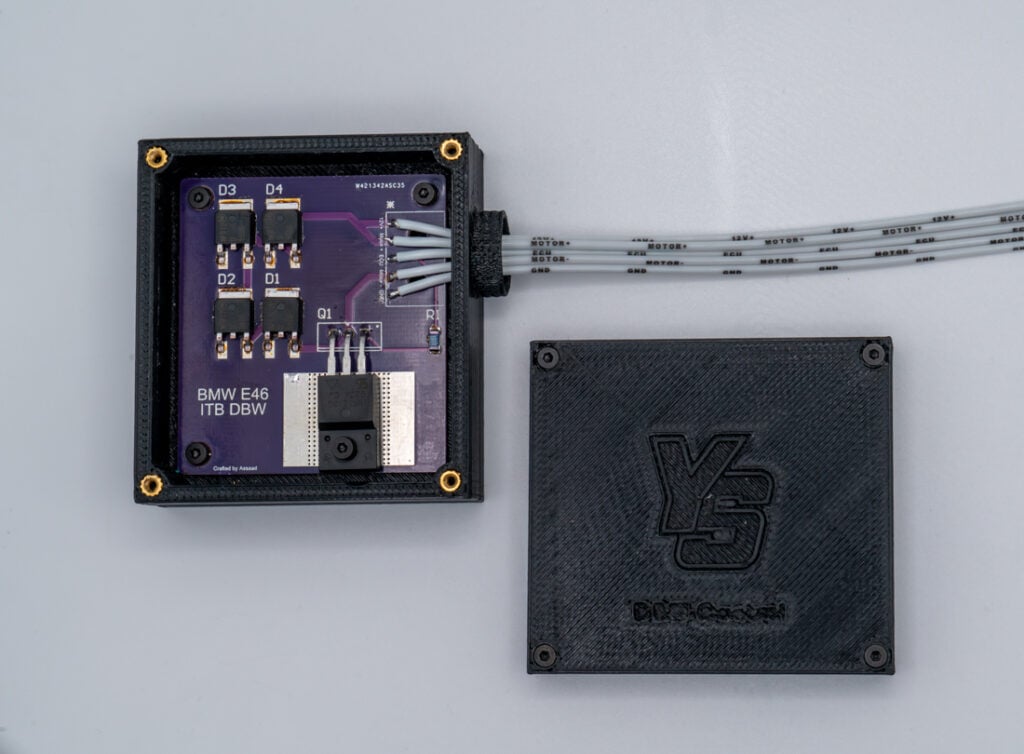

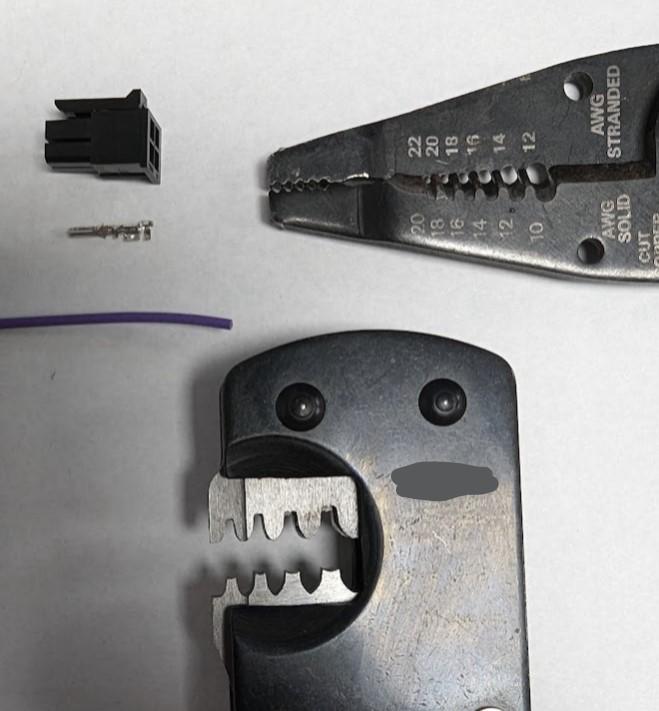

Poorly Placed Components

The placement of components on a circuit board is another critical aspect of design. Poorly placed components can lead to difficulties in assembly, maintenance, and heat dissipation. In a bad circuit board design, components may be clustered too closely together, making it challenging to solder or troubleshoot individual parts. Moreover, improper component placement can impede airflow and heat dissipation, leading to thermal issues that can affect the reliability and performance of the circuit board. Designers should carefully consider component placement to ensure accessibility, thermal management, and signal integrity.

Poor Use of Grounding or Power

Grounding and power distribution are fundamental aspects of circuit board design that can significantly impact performance and reliability. In a bad circuit board design, inadequate grounding or power distribution can result in ground loops, voltage fluctuations, and electromagnetic interference. Improper grounding can lead to noise coupling between components, affecting signal quality, and causing malfunctions. Similarly, inadequate power distribution can result in voltage drops, power supply noise, and insufficient current capacity. Designers must implement proper grounding techniques, such as star grounding and ground planes, and ensure robust power distribution to minimize noise and ensure stable operation.

Overly Complicated Tracing

While intricate circuitry may be necessary for complex electronic devices, overly complicated tracing can introduce unnecessary complexity and increase the risk of errors. In a bad circuit board design, overly complicated traces may be convoluted, hard to follow, or prone to manufacturing defects. Complex routing can lead to signal reflections, impedance mismatches, and difficulty in identifying and resolving issues during testing and debugging. Designers should strive for simplicity in tracing, using hierarchical design techniques, signal integrity analysis, and design rule checks to streamline the layout and ensure robust signal integrity.

The design of a circuit board plays a critical role in determining the overall performance, reliability, and functionality of electronic devices. By addressing key factors such as tracing, component placement, grounding, and tracing complexity, designers can create circuit boards that meet high standards of quality and effectiveness. A good circuit board design ensures optimal signal integrity, thermal management, electrical performance, and reliability, while a bad design can lead to a myriad of issues that compromise the functionality and longevity of the electronic device. By considering the variables discussed in this article and adhering to best practices in circuit board design, designers can create high-quality circuit boards that meet the demands of today’s complex electronic systems.

Remember, a well-designed circuit board not only functions correctly but also provide ease of manufacturing, testing, and maintenance. It is essential to invest time and effort in the design phase to prevent costly errors and ensure the success of the final product. Whether you are a seasoned professional or a novice in circuit board design, understanding the principles of good design and avoiding common pitfalls will help you create reliable and efficient electronic devices that meet the needs of your users.

In conclusion, the difference between a good circuit board and a bad one lies in the attention to detail, adherence to best practices, and understanding of the fundamental principles of circuit board design. By focusing on factors such as tracing, component placement, grounding, and tracing complexity, designers can create circuit boards that excel in performance, reliability, and functionality. A good circuit board design is not just a blueprint; it is a testament to the designer’s skill, knowledge, and commitment to excellence in electronic design.

If you have any further questions or need more information on circuit board design, feel free to contact us at YourSpec. Thank you for your interest, and happy designing!