The automotive industry and YourSpec has always demanded high standards for its electrical wiring due to the harsh environments and critical performance requirements of vehicles. One particular type of wire that stands out for its reliability and efficiency is TXL 24 AWG wire. This wire is designed to meet the stringent specifications of the automotive industry and is a preferred choice for many manufacturers and repair technicians.

What is TXL 24 AWG Wire?

Characteristics and Composition

TXL 24 AWG wire is a type of thin-wall automotive primary wire. The “TXL” designation refers to thin wall, cross-linked polyethylene insulation, while “24 AWG” indicates the American Wire Gauge size, which is a standard measure for the diameter of the conductor. The cross-linked insulation provides excellent resistance to heat, cold, and chemical exposure, making it ideal for use in automotive environments.

Performance and Durability

TXL wires are known for their ability to withstand high temperatures, typically up to 125°C. They are also designed to be lightweight, which is a critical factor in automotive design to improve fuel efficiency and reduce emissions. The TXL 24 AWG wire, being a smaller gauge, is used primarily for low-current applications such as sensors, instruments, and car interiors where space is limited and flexibility is required.

Applications of TXL 24 AWG Wire in the Automotive Industry

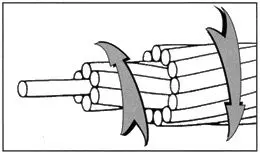

In-Vehicle Wiring Systems

TXL 24 AWG wires are commonly used in wiring harnesses, which are groups of wires bundled together to transmit electrical signals and power in vehicles. These harnesses are intricately designed to fit specific vehicles and can be found throughout, from the engine bay to the dashboard to the lighting systems.

Sensor Connections and Signal Transmission

The automotive industry has seen a significant increase in the number of sensors and electronic components used in modern vehicles, which require reliable and precise connections. The TXL 24 AWG wire is perfect for these applications due to its small diameter and high performance, ensuring that electronic signals are transmitted without interference.

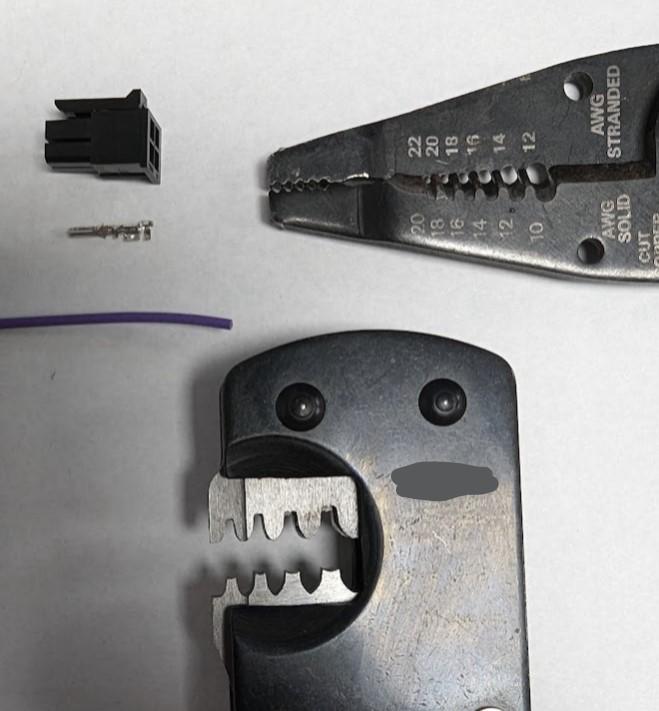

Aftermarket Upgrades and Repairs

For aftermarket installations and repairs, the TXL 24 AWG wire is often the wire of choice. Its durability and resistance to environmental factors make it suitable for applications such as audio systems, alarms, and accessory installations. Automotive enthusiasts and professionals alike appreciate the consistent performance and ease of handling that this wire provides.

Advantages of Using TXL 24 AWG Wire

Enhanced Safety and Reliability

Safety is paramount in the automotive industry. TXL 24 AWG wire’s heat resistance and durability contribute to safer electrical systems by reducing the risk of wire melting or short-circuiting, which can lead to vehicle malfunctions and accidents.

Compliance with Automotive Standards

TXL 24 AWG wire meets SAE J-1128 standards, which specify the performance requirements for insulated automotive wires. Compliance with such standards ensures that the wire is suitable for the demanding conditions of automotive applications and contributes to the overall quality of the vehicle.

Flexibility and Ease of Installation

The thin-wall insulation of TXL 24 AWG wire not only reduces weight and size but also provides greater flexibility, making it easier to route through tight spaces in vehicles. This flexibility, combined with the wire’s robustness, makes installation quicker and more efficient, which is crucial in both manufacturing and repair scenarios.

TXL 24 AWG wire is a vital component for automotive electrical systems, providing the necessary performance, safety, and efficiency required in modern vehicles. Whether for OEM manufacturing or aftermarket modifications, this wire continues to be a dependable choice for professionals who demand the best in automotive wiring solutions.