A request we receive often is to add wire striping to our service list. While we see the value of striping a wire, we want to make the argument that laser marking is a more potent tool. In this article we’ll cover the processes of both and advantages/disadvantages.

Striping Wire

A striped wire is a wire of a certain color which contains a painted continuous or dotted strip of another color. By striping wires of the same or similar color in a wiring harness the wires can be uniquely identified with a reference to the color and stripe details. This reference can be used to look up the purpose of the wire in the harness.

However, striping is not perfect. Over time, the striping can fade and become difficult to identify. This is especially an issue near heat. Striping is done by painting the stripe on top of the wire’s insulation, so degradation and fading of the paint can occur at different rates between the strip and base insulation. We experience this regularly firsthand when reverse engineering harnesses for some older vehicles. We commonly have issues identifying pink, grey, and white stripes from each other with some base colors.

Another thing to consider with striping is that it is just a reference. It does not define an actual purpose of the wire – that information must still be read from another source using the stripe as reference.

At YourSpec, we want to make our service as powerful as possible for our customers. However, tooling for striping is inefficient and messy. Offering striping on a per wire basis would be difficult to implement without being very expense and adding processing time to our orders.

Laser Marking

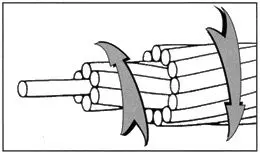

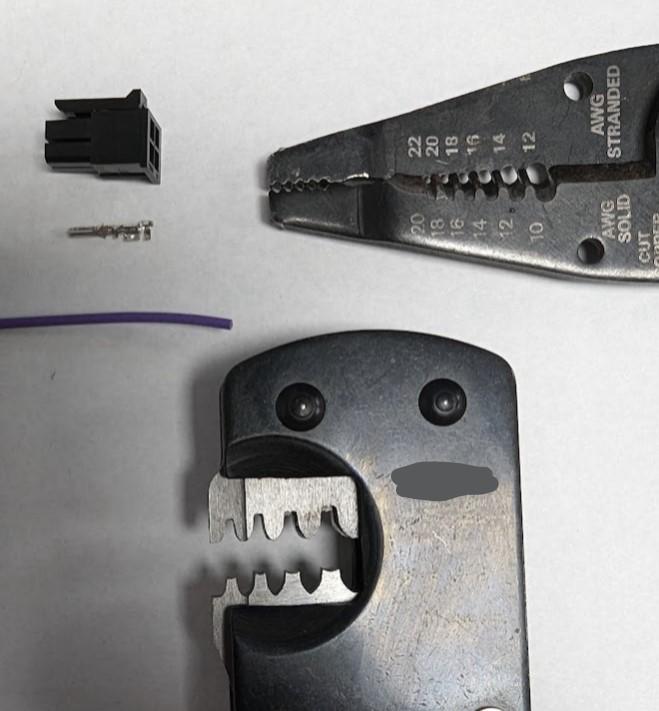

The process of laser marking wire uses a UV laser to create readable text directly on the wire. The UV laser creates this labelling by reacting to Titanium Dioxide (TiO2) in the wire’s insulation to permanently change the pigment in the wire insulation. TiO2 has a high concentration in Tefzel wire but is found in other types as well. Because the insulation material itself is changed, the marking cannot be removed without damaging or covering the insulation itself. This type of wire identification is used in military an d aerospace applications because it does not compromise the integrity of the wire and is highly resistance to removal and fading. This process conforms to Boeing BAC5152, D6-3691, MIL50881, and AS50881 standards. Also, to international standards of legibility of print SAE ARP5607 and SAE AS5649.

Laser marking wire has many advantages. Unlike striping, wire marking can be more than a reference. It can contain detailed information about the purpose of the wire, its installation location, or termination details. Striped wires will always require cross referencing documentation, however marked wires can potentially save time in avoiding that cross referencing. However, one of the benefits of marking is that it is fully customizable. As much or as little information can be included as desired. With our personal projects at YourSpec, we tend to be on the descriptive side with our marking by defining the termination pin and the end component. We find it saves us time in assembling and diagnosing by reducing the amount of time we spend referencing source materials.

Wire marking is not perfect. Because it depends on TiO2 in the wire insulation there may be inconsistency between the marking color and appearance across different wire colors and gauges when using wire types such as TXL. Very rarely some combinations may not contain enough TiO2 to get a highly readable marking with good contrast. In those cases we always let the user know that they may wish to change the selection of wire they are using.

The biggest drawback to wire marking is cost and availability, part of the reason we started YourSpec. At YourSpec our goal is make accessing professional wire processing services such as laser marking easy and affordable for projects of all sizes!